Building a Military-Style Titanium Field Watch

My stepson just bought his first home. He mentioned to my wife that he sometimes doesn't carry his mobile phone and should get a wristwatch that he could wear all the time. That was all the excuse I needed to start a new watch project with the goal of giving it for his 39th birthday in September 2024.

This was June 2024, so I began thinking about possible designs. He's a truck driver and an Army veteran, and my thoughts were he would prefer something rugged and readable instead of delicate and/or overly styled. Watches designed for outdoor or military-use fall into a few categories: dive, pilot, and field watches. These can be thought of corresponding to the Navy, Air Force, and Army from a military branch point of view, so I started focusing on the field watch design.

Wristwatches for men were not a thing until WWI, when soldiers and airmen started operating war machinery like airplanes and tanks. The Cartier Tank design and Rolex Oyster were designed in this period and are still iconic watch models today, 100+ years later.

In WWII, both the Allies and Axis powers issued watches specifically designed for soldiers and airmen, and the "field" watch was an easy-to-read design adapted by Allied armies, featuring a simple case, large numerals, and luminescent markers.

Multiple watch manufacturers in the US made field watches and continued to do so into the Vietnam War period. Here's a web page that talks about Vietnam-era field watches. The new DoD spec added luminous markers and 24-hour numerals to the dial.

.

The Vietnam field watch above became the design target for this build. I had a genuine Swiss ETA 2824-2 automatic movement on hand from a previous project, so the case, dial and hands needed to be compatible. At first I tried to find a larger case in the 42mm diameter range, but those were mostly dive watch designs with moving bezels. I also wanted good water resistance (over 100m depth) and a sapphire crystal for toughness and all-weather use.

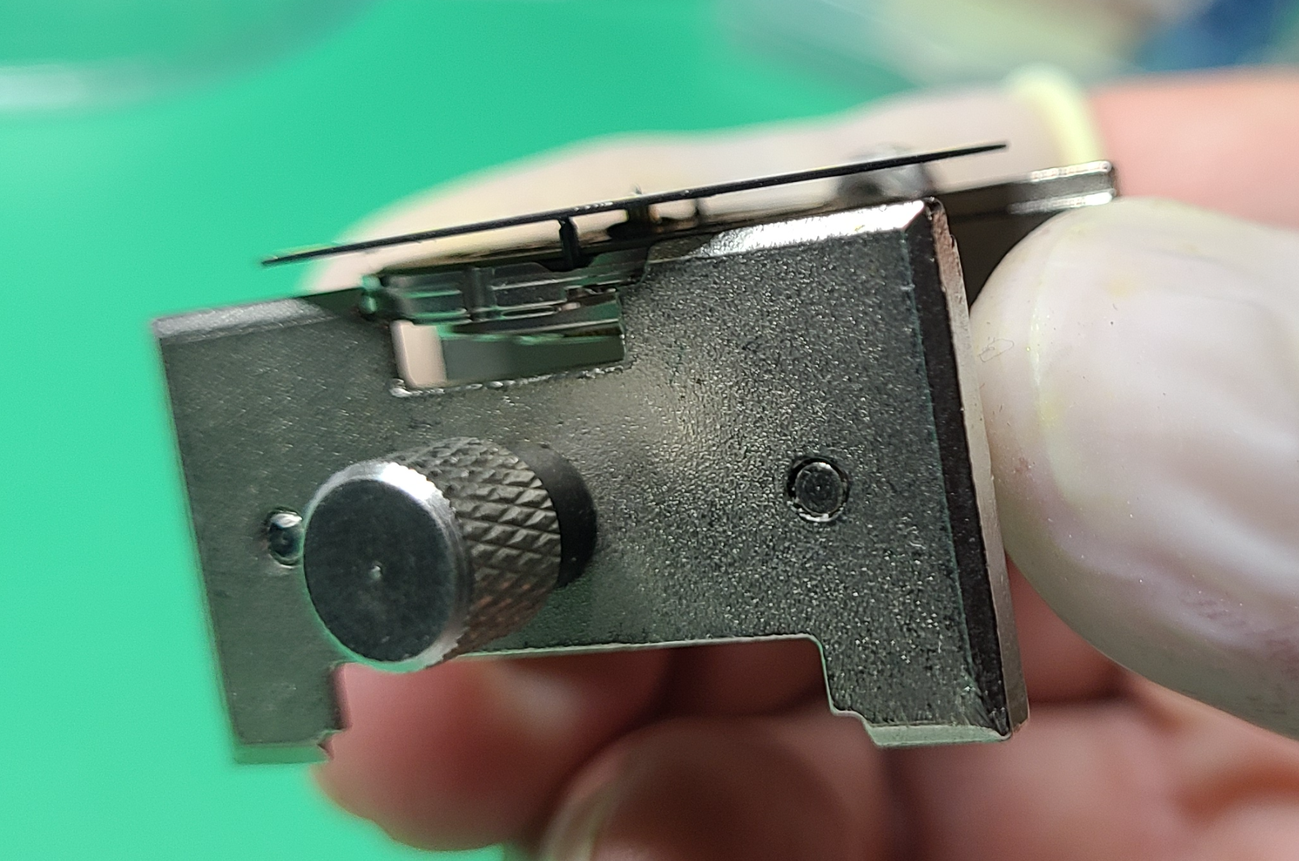

I found the perfect dial & hands package with nearly identical design on eBay, even down to the vintage yellow luminescent markers. The same seller offered a no-nonsense 39mm brushed titanium case with anti-reflective sapphire crystal, solid case back, 20mm lug width, screw-down crown, and 200m water resistance. The case is tough but lightweight at only 29g (1 oz).

The last choice to make was what kind of strap or bracelet to install. Most period photos show the field watch on an olive canvas or brown leather strap, but there are new materials available now that are more durable than plain cowhide. I leaned toward a tough synthetic material strap with buckle, maybe with an olive or desert tan color, but my wife suggested it would look best with a black strap. In the end I ordered two types, the first a hybrid sailcloth + silicone rubber and the second in thick, high quality black leather with white contrast stitching. Both have captive quick-release spring bars to make it easy to change without tools. They also both have brushed stainless steel buckles to match the brushed titanium case. I figured he could choose the one he liked best (or get something different).

Sailcloth/rubber (L) and black cowhide (R) straps

While waiting for the dial and case to arrive, I tested the movement to check timing and adjust the regulation rate and beat error. Gave it a full wind and demagnetized, then put it on the Timegrapher.Testing the regulation of the movement with the Timegrapher

Mechanical movements are sensitive to the direction of gravity. The force of friction in the geartrain and balance changes depending on whether it is lying flat (dial up, dial down) or hanging, i.e., when the dial is parallel to gravity. Checking performance in 7 orientations (2 flat + 5 hanging) gives these results:

Measurement results for the uncased movement

Both amplitude (how strong the balance or "heart" of the movement beats) and the rate (deviation in seconds per day) are excellent. The beat error (lower is better) refers to how evenly the balance swings in each direction. In this case they match by 0.1 millisecond.

Bottom line is that this movement is running great and no adjustment is needed. I will check it again after installing it in the case with the dial, hands, stem, and crown.

The dial purchased is compatible with 3 different movements from ETA, Seiko, and Miyota. As such it comes with 6 dial feet on the back instead of 2 needed to fix the dial to the movement. I removed four of the dial feet and smoothed off the nubs with the Dremel.

Next, the dial is mounted to the movement and secured with hinged clamps.

Dial being fitted to movement

Next comes installing the hands. Some of the original field watches had red- or orange-tipped seconds hands, so I decided to paint the arrowhead on the tip of the white seconds hand with orange enamel.

Then I aligned and installed the hour hand, minutes hand, and the seconds hand using the hand pusher tools..

Now it's starting to look like a watch. To encase the movement, I set the case over the dial/movement and aligned the '3' to the crown tube on the right, then reinserted the stem. By the way, the crystal (glass) looks messy because it is still covered with a protective film which I leave on until it's delivered.

Assembled watch before trimming the winding stem

The watch assembly is almost done save for the case back, but first I check the rate on the Timegrapher to assure that the movement is still running well. The watch is running at a rate of 2 seconds fast per day, which is excellent for a mechanical movement. The amplitude is high at 314, which means that the movement is well-lubricated and has plenty of power from the mainspring. The beat error is 0.1ms, which means that the "tick" and the "tock" of the balance wheel are matched within 1/10,000 second, again excellent.

Timegrapher results after casing - dial-up

Mechanical movements are sensitive to orientation to gravity, however. If the dial is flat to the ground, as in the dial-up photo above, there is less influence of gravity. However if the dial is parallel to the force of gravity, the balance wheel motion can be impacted. I tested it again in the 12-up position and saw a noisy trace on the tester instead of a smooth line. I saw varying result in other positions, so I wound it fully, demagnetized it, and checked again, and it was still noisy.

Timegrapher results after casing - 12-up

In the end, I removed the winding rotor, which was not rotating smoothly, and lubricated it. That seemed to eliminate the noise in the trace.

Finally, the case back is installed with its silicone O-ring for water resistance. This case is advertised to be water resistant to a depth of 200 meters. However, I have no way of testing it, so let's just say it should be fully protected in a rain storm. Then I install a temporary strap for testing.

I usually wear a newly built watch for up to 3 days to make sure it continues to work properly. I set the time exactly to the second on the first day, then check the watch time against the actual time periodically to see if it winds itself and runs accurately both while worn and while sleeping. I record the Timegrapher results in 7 positions each day to see if anything changes.

Wrist tuning log results over 3 days

In this time span of 60 hours wearing the watch during the day, and setting it down at night, it gained a total of 6 seconds for a accuracy rate of +2.5 seconds every 24 hours. Note that in that time I didn't hand wind it via the crown at all -- it wound itself via the automatic winding rotor. This performance is quite excellent for a mechanical watch, if I do say so myself.

Here are shots of the watch with both straps, first the tan sailcloth & rubber, and second the black calfskin with white stitching.

Final product with straps: sailcloth/silicone (L) and cowhide (R)

Update 14-Aug-2024: I had the opportunity yesterday to give Matt the watch. Here he is wearing it with the black strap. I had an extra NATO strap in olive that I thought might go well with the military look, so I included that in the box with the other two straps. He ended up putting on the NATO to wear, at least for now. That's why I included it!

No comments:

Post a Comment